Machine Operations

- 5 Axis CNC Digitizing

- Automatic Tool Changer

- CNC Head Porting

- Cylinder Boring

- Cylinder Head Resurfacing

- Lifter Boring

- Line Boring

- Multi Purpose CNC (Custom Parts)

- Thrust Cutting

Product Details

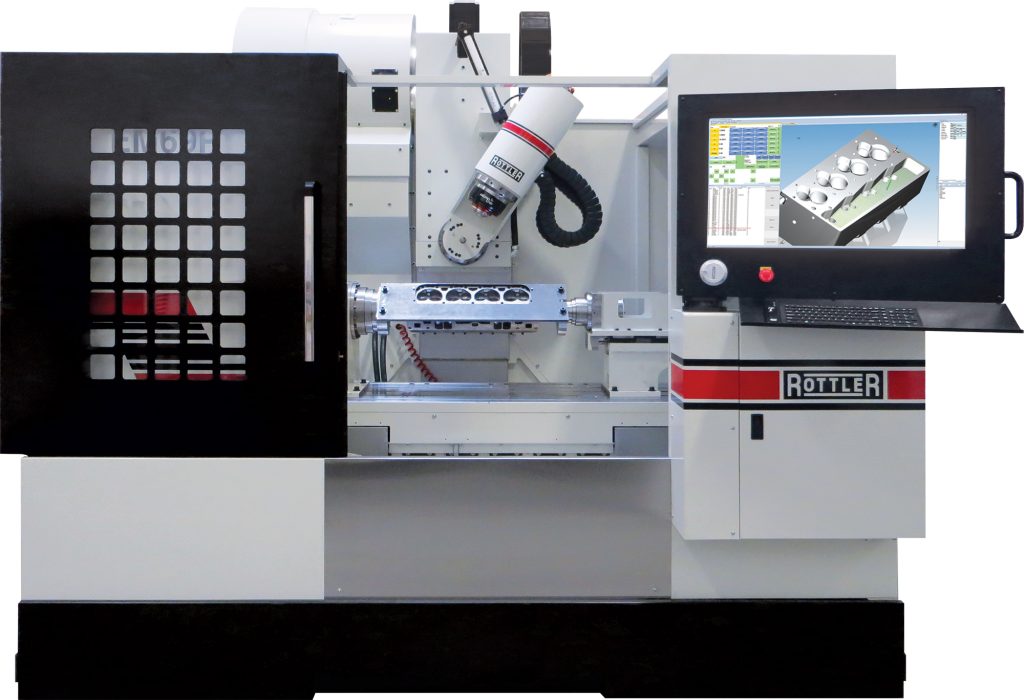

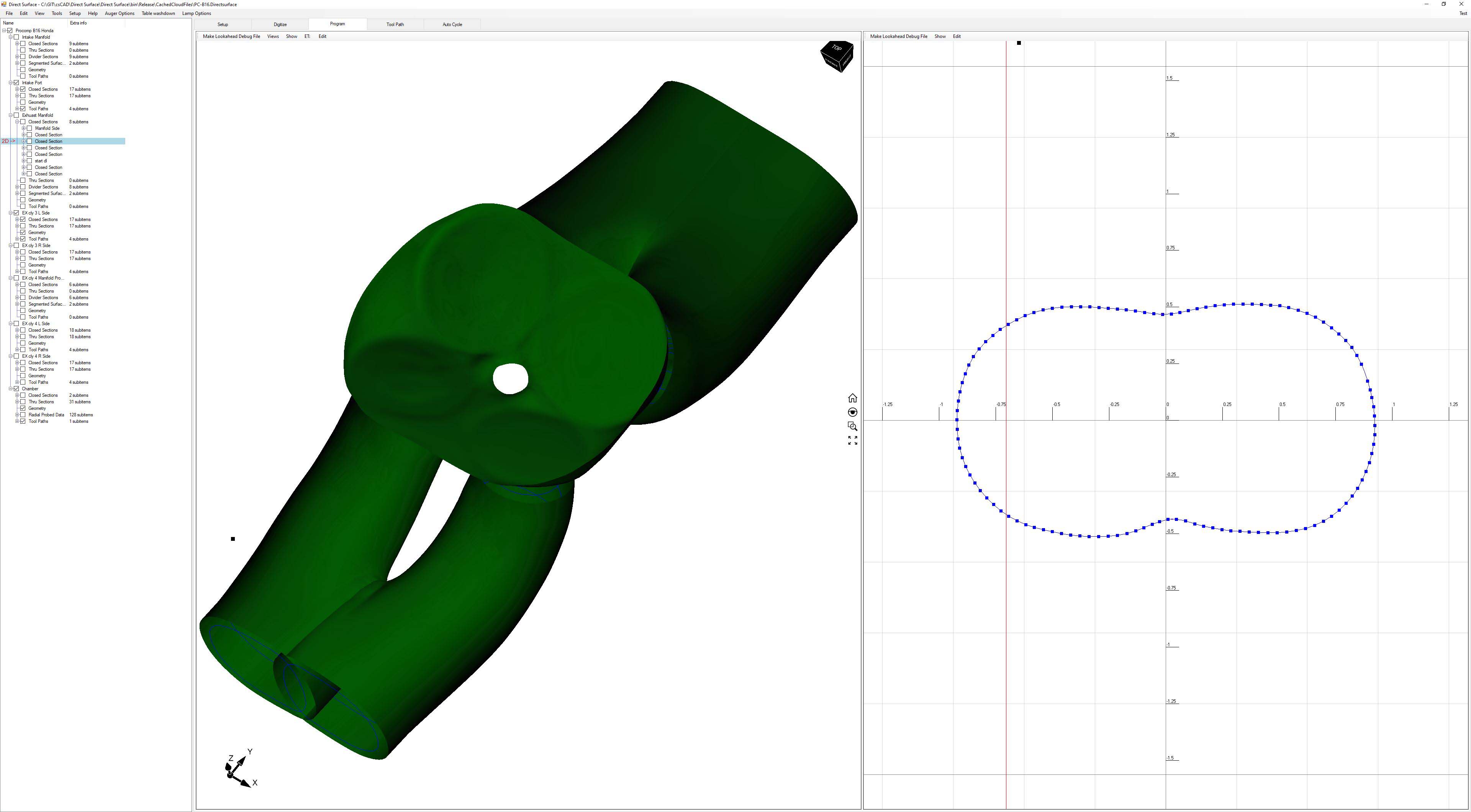

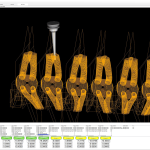

Rottler’s Next Generation 5 Axis CNC Multi Purpose Machining Center offers the precision and speed needed to reproduce cylinder heads with exceptional accuracy – with no handwork needed. The EM69HP also has the capability of porting intake manifolds with the same techniques used to port cylinder heads while also perform engine block jobs such as boring, surfacing, lifter boring, line boring, lightening and engraving, plus many additional machining requirements.

- Advanced High Speed Spindle Motor with increased power 43HP 32kW continuous and speed up to 20,000RPM.

- With the use of Rottleer PATH – Rottler Computer Aided Manufacturing Software allows general CNC industrial machining for a wide variety of applications.

- The EM69HP has very fast rapid movements and cutting speed with infinite look-a-head capabilities offering fast production times.

- Digitizing is done automatically on the machine using a Reinshaw probe, eliminating the need for an expensive coordinate measuring machine (CMM). All programming and operations are done directly on the Rottler EM69HP 32” Touch Screen Control Panel.

- The 24 tool automatic tool changer is included as standard equipment for “set it and forget it” operation.

- The EM69HP uses the exclusive Rottler CNC Touch Screen Control Software. With standard Windows user interface and animated training, training time and learning time is reduced. Operators can take full advantage of available features that will improve operator speed and efficiency. See details in “Control” section below.

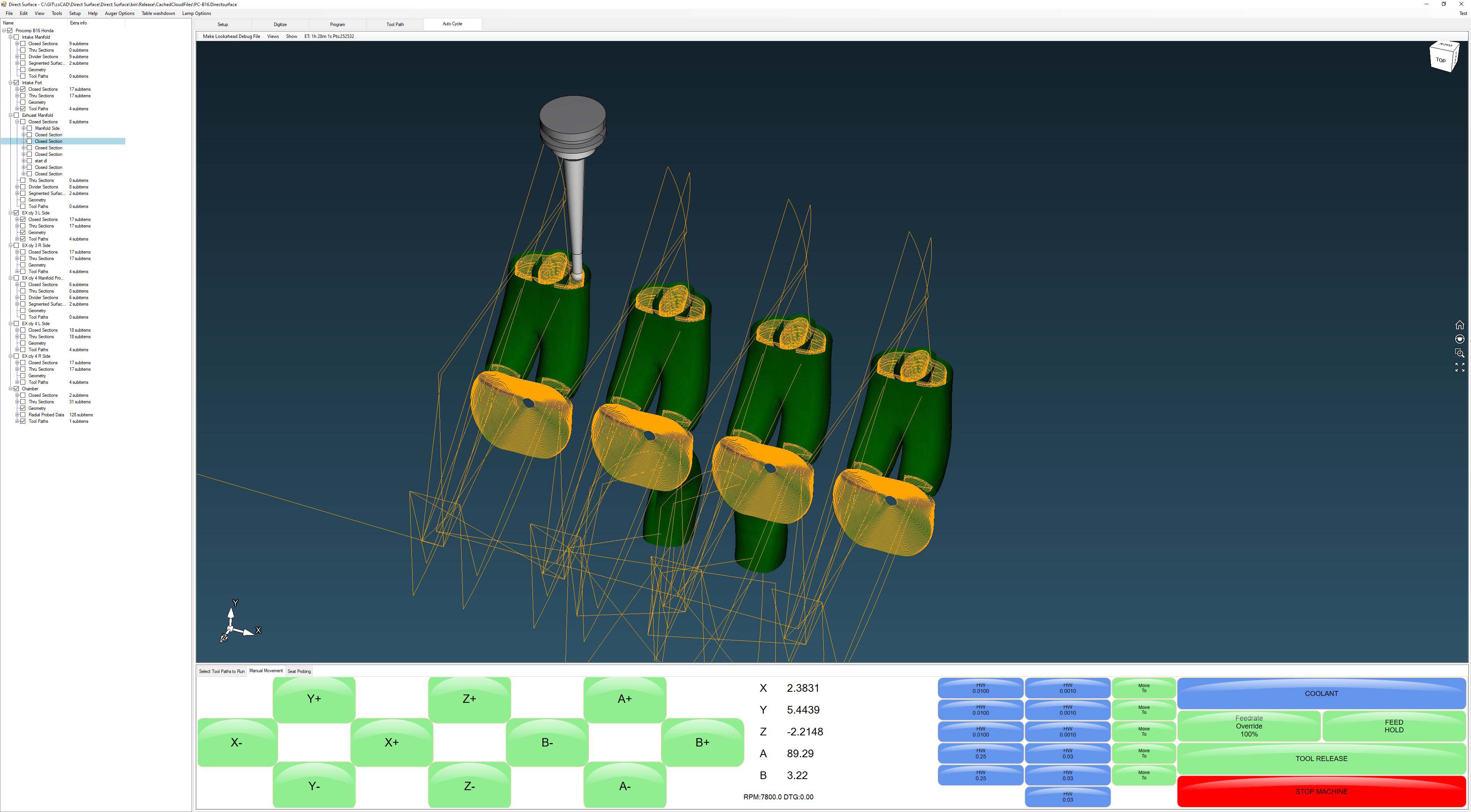

The EM69HP features Rottler’s Advanced Optional 4C Software. The PC-based single processor control system by Direct Motion is highly interactive and very responsive. Our next generation 4C control system extends capability to include importing of CAD models which can be automatically be converted in toolpath that the machine can then use to execute actual machining operations. The upgradeable software can be networked for enhanced efficiency. The Advanced DM software tools allow manipulation of port design and minimize digitizing time. This allows an operator to pick up data once and tweak the design (including hand-ported designs) as needed. See details in “Control” section below

Spindle in 5th Axis – The high torque spindle of the EM69HP is built into the 5th axis of the machine with the center of the cutting tool on the same center as the 5th axis. The spindle is able to tilt 60 degrees to the left and right.

This unique feature allows easier set up and faster porting time compared to fixed spindle machines.

Competitive machines have a fixed spindle and therefore have to tilt the cylinder head left and right which makes complicated programming and each port has to be programmed differently.

Touch Screen Technology – Rottler utilizes a 32” TOUCH SCREEN to simplify machine control operation. Touch screen allows separate control panels to display only the information and control buttons that are required for that particular operation to be displayed and hide the information and buttons not required. Most CNC machines have large control panels with many unnecessary buttons and this makes learning the machine slow and complicated, which is stressful to a new operator.

Instant Internet Support – Rottler offers cutting edge internet support direct from your machine to the factory. Skype is installed for internet support. This feature gives you instant, direct contact with Rottler right on the machine without even making a phone call.

Automatic Tool Changer – The 24 tool automatic tool changer is included as standard equipment for “set it and forget it” operation.

Pre-Arrival and On-Site Training Available – Rottler offers training videos and guidelines as well as factory training prior to delivery of your EM69HP as well as on-site training after delivery. Rottler’s EM69HP is so easy to learn most operators are on their own within three to five days. Once your EM69HP order is confirmed, a software package including a course of training videos and instruction guidelines will be sent to you so that the operator can start learning the software before the new machine even arrives. Should you feel that extra training is required before the arrival of the machine, Rottler offers optional, additional hands-on factory training.

Simplicity – The simplicity of the complete process from digitizing to programming to actually machining the heads is an important feature. Rottler has developed this system for over 12 years, making the Rottler EM69HP a system that is easy and fast to learn. The EM69HP will start paying for itself by reproducing heads fast within 3 days of training!

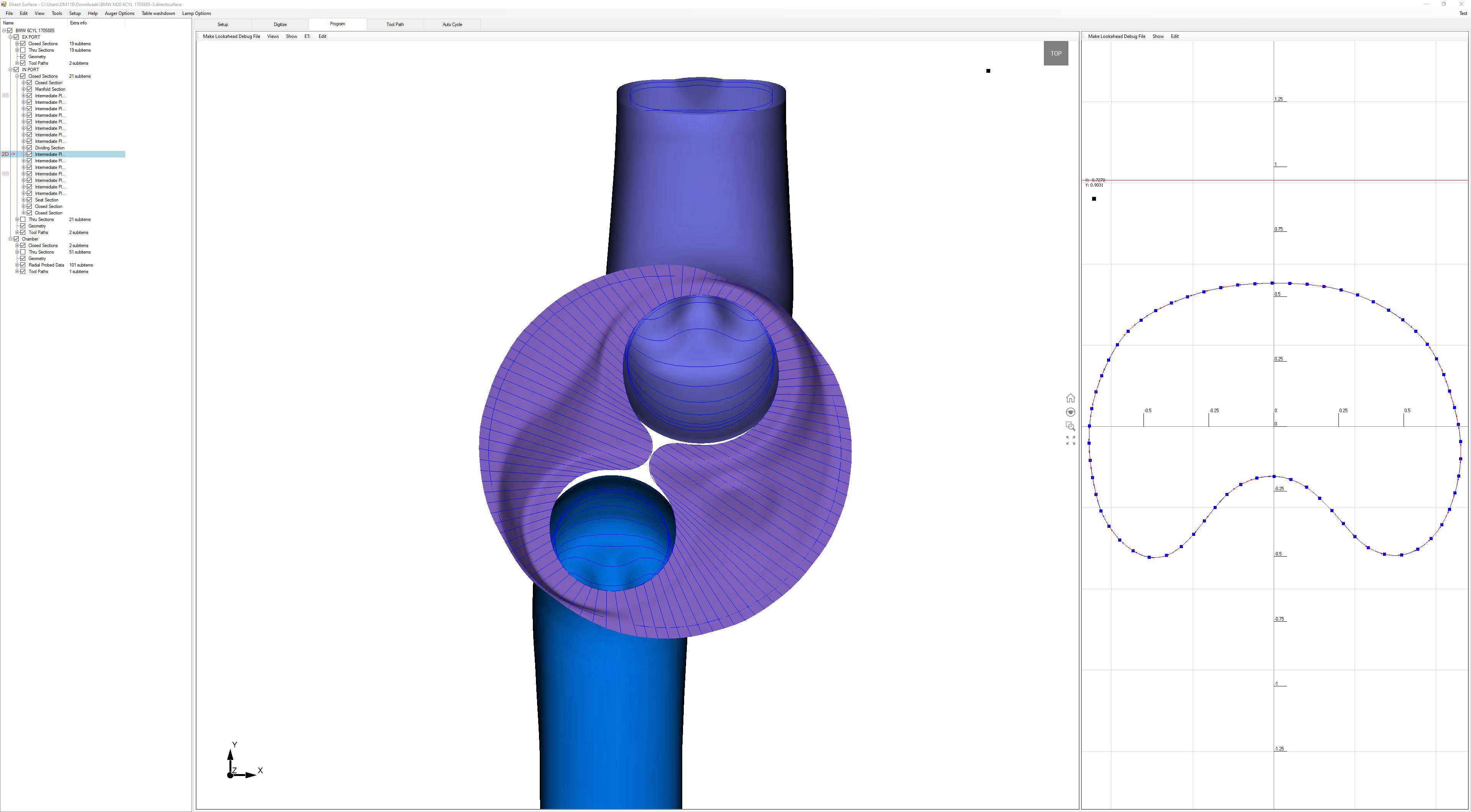

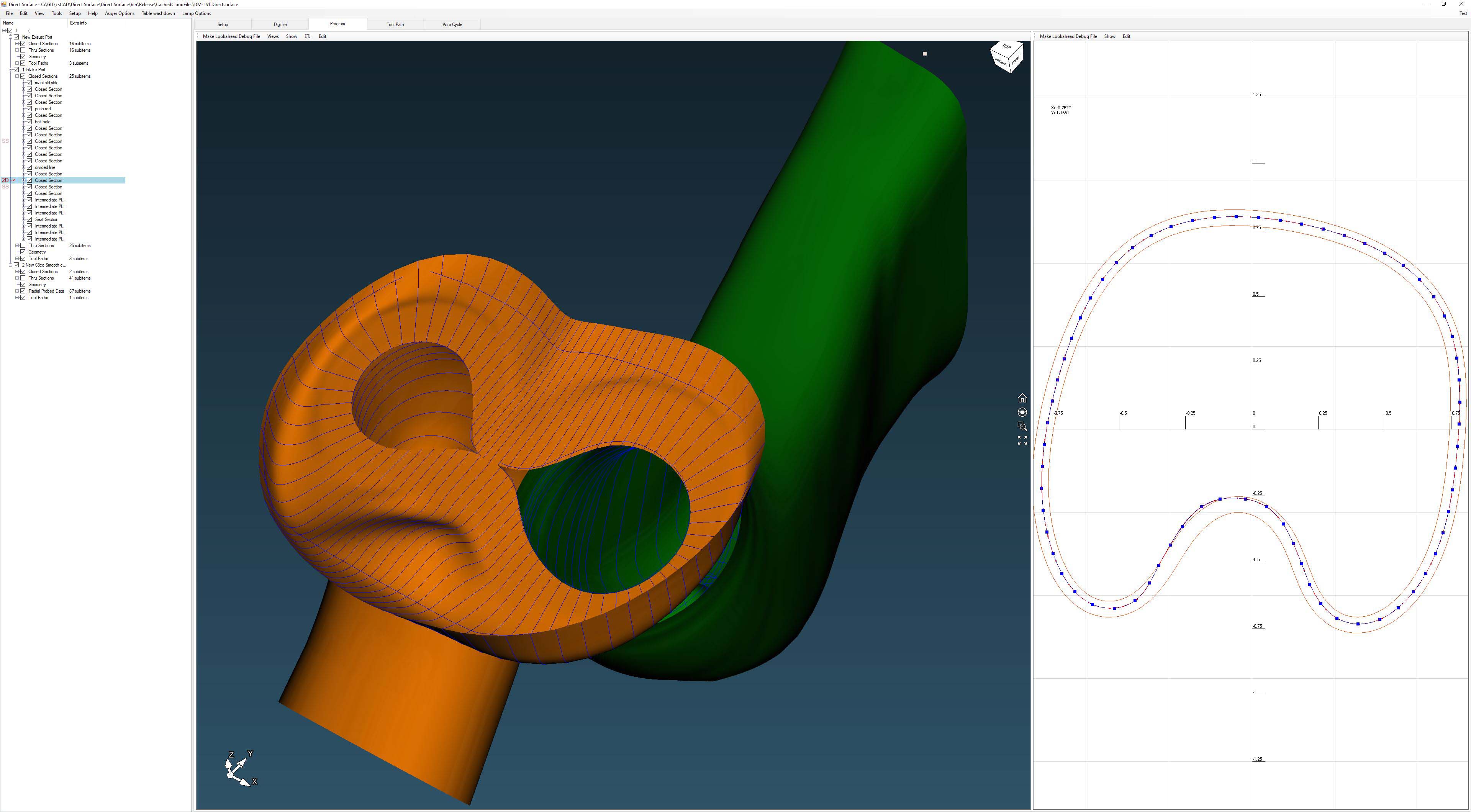

Exclusive 4C Control – What is 4C Software? Rottler’s newest EM Series equipment offers Computer Numeric Control (CNC), Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) in the industry’s most advanced Computer Measuring Machine (CMM). The 4C technology allows users to digitize, edit designs and begin cutting in less time but also requires less machining/programming expertise compared to many other systems. This brand new, revolutionary CNC machine CAD/CAM software allows 3D CAD Solid Models to be imported or created at the machine – the built-in CAM functions can be used to semi automatically and interactively create complex 3D tool paths direct from the CAD geometry.

Unique Features – All-in-one digitizing/probing, programming and porting machine – nothing else required! And it’s all done in one software package. All other systems use 3-5 software programs for each operation, each requires it’s own long learning curve. We do digitizing, surface programming, surface modifications (if need be), toolpath generation and operation of the machine from one common program!

Tooling Packages – Rottler offers complete packages including all necessary software, fixtures, tool holders and porting tools.

Turn-key Package Includes: Machine, software, fixtures and tooling, training (at factory and/or on-site after machine delivery,) internet support (internet connection to the machine computer – can be controlled remotely from anywhere in the world.)power and

The Rottler EM69HP 5 axis CNC universal machining center is a revolutionary comprehensive solution. Our user friendly touch screen software handles the entire digitizing, programming and porting process from start to finish. No outside software tools are needed, drastically reducing the learning curve and time spent on training. Advanced Rottler Software Allows Operator to View Cross Sectional Area and measure volume.

Dimension of Port Area and Volume

Software can calculate cross section area to ensure that actual cross section area is calculated as port shape changes

With the EM69HP software why hand port the first head? You can digitize the cast head and then use the EM69HP software to modify ports rather than grinding by hand.

Beautifully machined ports are accurate to close tolerances requiring no hand work. Rottler’s advanced port manipulation tools allow quick and easy “at the machine” modification of three dimensional data.

Advanced Direct Motion Software Tools

Allows manipulation of port design and minimizes digitizing time. This allows operator to pick up data once and modify the design on the screen. Operator can modify hand ported design if necessary.

Standard PC Hardware and Software

Offers the highest performance, can be networked, easily upgradeable and repairable.

All Inclusive Flexibility

Our all-inclusive system ensures that the end user never has to transfer design data from computer to computer or convert data between separate software programs saving time and avoiding hassle.

Our versatile software allows importing and exporting of designs between most common CAD/CAM software programs. This means Rottler customers are able to utilize previous knowledge and experience if familiar with another program such as Surfcam or Mastercam.

3D Arc Feature

The 3D Arc Feature allow operators to program an arc “through” the port and “around” the port. This is especially useful in the short turn of a port to mathematically define critical shapes. Using these features, changes to the 3D port can be made in seconds and is a useful tool in helping to develop the maximum flow in a port.

ROTTLER’S ADVANCED OPTIONAL 4C SOFTWARE

What is 4C Software? Rottler’s newest EM Series equipment offers Computer Numeric Control (CNC), Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) in the industry’s most advanced Computer Measuring Machine (CMM). The 4C technology allows users to digitize, edit designs and begin cutting in less time but also requires less machining/programming expertise compared to many other systems. This brand new, revolutionary CNC machine CAD/CAM software allows 3D CAD Solid Models to be imported or created at the machine – the built-in CAM functions can be used to semi-automatically and interactively create complex 3D tool paths direct from the CAD geometry.

One of the main features is the EM series’ expanded size 32˝ touch screen – by maximizing screen size, Rottler’s CAM software allows unprecedented amounts of information to be displayed for the operator’s use. The user can choose the information to be displayed for incremental and interactive functionality. 4C is available in 3, 4 and 5 axis modules to suit the application.

Exclusive Dimpling Feature

Customers using the unique Rottler software are able to dimple ports in certain areas reporting a 1½ – 2% increase in horsepower of non-dimpled ports. Not only are you gaining horsepower but you are preventing your competition from copying your exact port.

Exclusive Dimpling Pattern

Do you know why golf balls have dimples? To make them fly farther! By dimpling the surface of a golf ball, you eliminate surface area thus reducing drag of the air across the ball. By dimpling a port in the cylinder head, you can also reduce drag of the air going across the face of a port thus improving airflow. In tests of identical cylinder heads bolted on the same short block the dimpled ports reported an increased in horsepower on the dyno over heads that weren’t dimpled.

- High Speed Spindle Motor with increased power 43HP 32kW and speed up to 20,000RPM.

- A 24 tool Automatic Tool Changer is included. Tool changes are accomplished via a dual arm tool changer and rotary tool carousel traveling on linear slides in the Y axis for clearance.

- Optional Software System available for the machine:

- Port and Chamber CAD/CAM software to quickly manipulate port dimensions, view cross section area, calculate volume, create surfaces, create tool paths and machine ports and chambers. Requires CNC program – either ADP-PROBE4 digitizing system or Rottler PATH as detailed below.

- After an order is placed, the training videos on www.RottlerTube.com must be studied before Rottler training technician travels to the machine for onsite training. Operators must continue to view these training videos after training to keep up to date with operation of the control and up to date with the latest features.

- Internet connection to the machine computer must be provided and connected at all times during the use of the machine. This is required for service support. The control sends information to the Rottler service department.

- Customer must have laptop with videocam for software and programming support.

- Highly Interactive & Very Responsive PC Based Single Processor Control System by Direct Motion Control Technology

- Standard Windows User Interface with Animated Training & Remote Diagnostics

- CNC 32″ Touch Screen Control, Windows Operating System with Intel Processor, Networking and Internet Connection included.

- Internet enabled with the ability for a technician to “take over” the machine for remote training and diagnostics from anywhere in the world.

- Programming and Machine Operating through 19″ (500mm) extra bright touch screen.

- Precision Digital Readout, .0001″ (.002mm) Resolution.

- Accuracy ensures Ports will Line Up with No Step – No Hand Blending Required.

- 120 Degree Range of Motion on 5th Axis Tilt.

- Custom Specialized Cutters and Tool Holders Minimize Run Out, Chatter, Noise, Clogging.

- High Spindle Speeds (up to 20,000 RPM) with low speed torque for fast stock removal when machining billet castings and boring engine blocks.

- Linear Roller Bearing Slideway construction on all axes for smooth and precise axis movement.

- Direct Drive Precision Ground Ball Screws on all axes for improvement accuracy and repeatability.

- High Feed Rates of 100 IPM (2.5MPM) with Integrated Design & Sophisticated Look Ahead Software.

- Rotary Vector Gear Reducers in 4th and 5th Axis for extended life and near zero backlash.

- Direct Drive AC Servo Motors on all 5 axis – no belts.

- ABS Brushless AC Servo Motors.

- Linear Motion Slide Way construction for smooth and precise axis feed.

- Fully Enclosed with Sliding Doors and Coolant System with chip auger and roll out coolant tank.

| EM69HP Machine Specifications | American | Metric |

|---|---|---|

| Control | Rottler CNC | |

| Spindle – Motor Torque | 708in.lbs | 80NM |

| Slideway Type (X/Y/Z) | Linear Roller Bearing Slideways | |

| Axis Feed Method (X/Y/Z) | Direct Coupled Servo Driven Ball Screw | |

| Table – Size | 19.68″ x 59.09″ | 500 x 1500mm |

| Table – T Slots | 5 | |

| Travel – Horizontal (X Axis) | 39.4″ | 1000mm |

| Travel – In/Out (Y Axis) | 19.68″ | 500mm |

| Travel – Vertical (Z Axis) | 30″ | 762mm |

| Travel – Spindle Nose to Table | 40″ | 1016mm |

| Spindle – Taper | CAT40 | |

| Spindle – Rotation Speed | 0 to 20000 RPM | |

| Coolant Capacity | 84.5 Gallons | 320 Liters |

| Weight Capacity | 1543lbs | 700kgs |

| 5th Axis Rotation | 120deg (+/- 60 Deg) | |

| Feed Rate | 0-100ipm | 0-2.54mpm |

| Tool Changer – Number of Tools | 24 | |

| Tool Changer – Maximum Weight of Tool | 15.4lbs | 7kgs |

| Tool Changer – Maximum Length of Tool | 11.8″ | 300mm |

| Dimensions – Machine | 111.30D x 119.09W x 108.07″ H | 2827D x 3025W x 2745mm H |

| Dimensions – Floor Space Requirements | 136.22D x 170.67W” | 3460D x 4335Wmm |

| Dimensions – Shipping | 90D x 121W x 110″ H | 2286D x 3073W x 2794mm H |

| Machine Weight | 11500 lbs | 5546 kg |

| Electrical Requirements | 208-240V, 60A, 50/60Hz, 3Ph | |

| Air Requirements | 1 cfm @ 90 psi | 28 l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) | |