Multi Purpose CNC MACHINES

ROTTLER

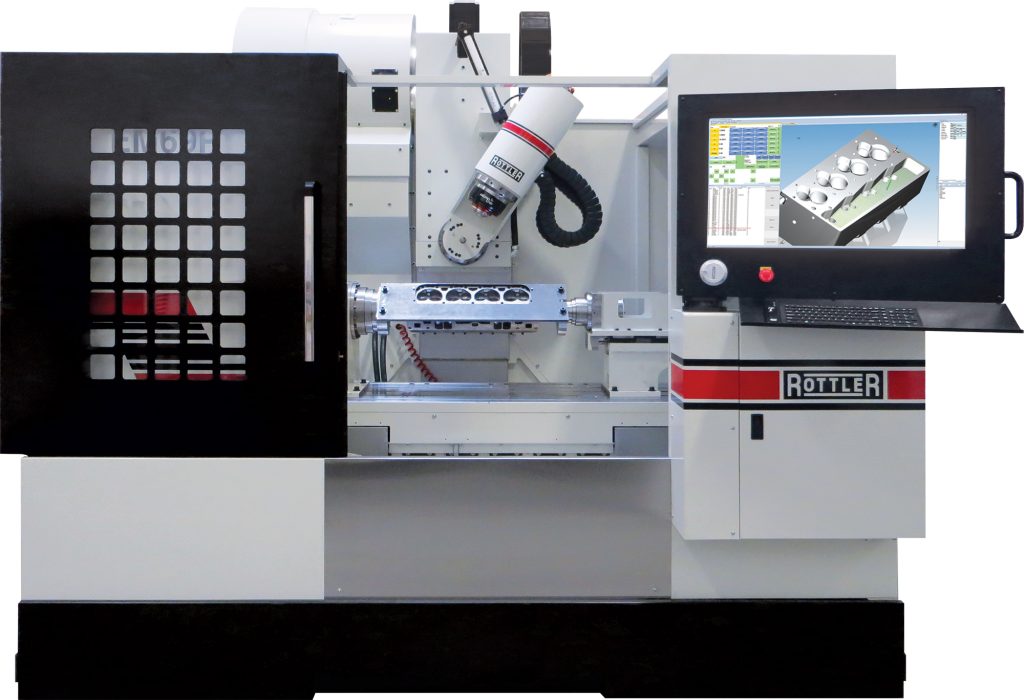

F69A

The F69A is a truly amazing machining center. Blueprint bore, line bore, deck blocks, surface heads, true lifter bores, automatic milling to size, all in fully automatic operational modes

ROTTLER

EM69ATC

The EM69ATC 3 and 4 axis CNC Machining Center is versatile and great for machining engine blocks and making custom parts with a 24-tool Automatic Tool Changer

ROTTLER

EM69HP

The Next Generation 5 Axis CNC Multi Purpose Machining Center offers the precision and speed needed to reproduce cylinder heads with exceptional accuracy with no handwork needed

ROTTLER

EM79

The EM70 Series machines are designed for both the small- to medium-size diesel engine rebuilder and remanufacturer as well as the performance racing engine builder

ROTTLER

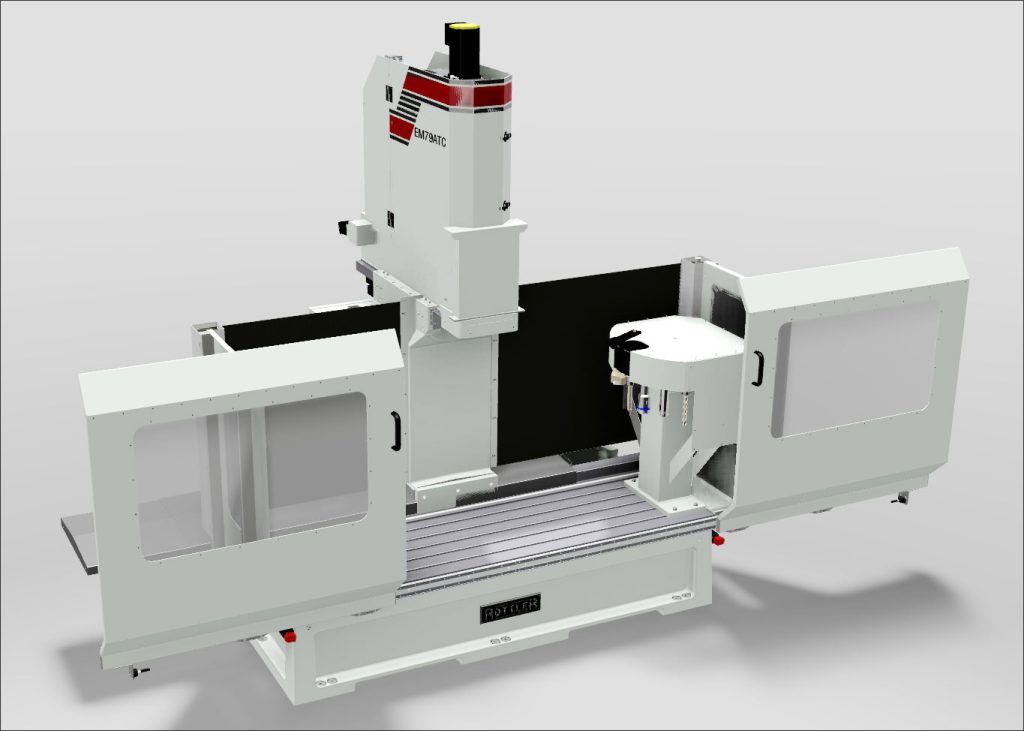

EM79ATC

The EM70 Series are designed for the small – medium size diesel engine rebuilder as well as the performance engine builder. The EM79ATC features an Automatic Tool Changer

ROTTLER

EM103H

The EM103H is designed for machining smaller engine blocks used in ‘On Highway’ applications such as trucks and buses, as well as mid range size blocks

ROTTLER

EM104H

The EM104H is designed for machining large engines used in the earth-moving, mining, oil and gas, power generation and marine work boat industries

ROTTLER

EM105H

The massive EM105H is designed for machining large engines used in the earth-moving, mining, oil and gas, power generation and marine work boat industries up to V20 engines blocks

ROTTLER

EM107H

The EM107H is manufactured to handle the world’s biggest and heaviest engine blocks. It can quickly, accurately and affordably eliminate the costly downtime of big engine failures

ROTTLER

EM109H

The EM109H is a massive machine manufactured to handle very large and heavy engine blocks and is exceedingly capable of performing such jobs as boring, surfacing and line boring.

ROTTLER

F9A

Designed for all automotive blocks up to big block V8’s and small diesel blocks, the F9A will produce accurate bores for a lifetime

ROTTLER

F10A

The F10A Boring Bar has been designed for standard and large capacity machine work. The spindle diameter is larger than that of the F9A

ROTTLER

F10X

The F10X uses Rottler’s exclusive Xcelerate technology to make operation faster and offers automatic hole-to-hole unattended boring