Machine Operations

- Automatic Tool Changer

- Block Surfacing

- Blue Print Boring

- Boring & Sleeving

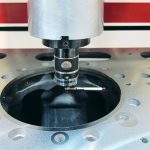

- Circular Interpolation

- Connecting Rod Boring

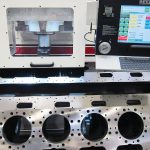

- Cylinder Boring

- Cylinder Head Resurfacing

- Lifter Boring

- Line Boring

- Multi Purpose CNC (Custom Parts)

- Thrust Cutting

Product Details

The massive EM105H is designed for machining large engines used in the earthmoving, mining, oil and gas, power generation and marine work boat industries up to the size of V20 engines blocks such as the CAT3520 and C175 v20, MTU 4000 V20, Cummins QSK78, Waukesha 9390, etc.

The EM100 Series employ an entire array of features which help maximize the productivity capabilities of the machines. Quick tooling changeover maximizes the versatility and flexibility of the machine, allowing boring and surfacing in one setup. The machines work like advanced CNC machining centers but Rottler’s conversational programming technology makes them very easy to operate.All EM100 Series machines have the capability of Boring, Surfacing, Line Boring, and Universal Machining. Traveling column and spindle movements operated by precision ball screws and AC servo motors. Optional Automatic cycle software and production tooling allow complete block banks to be machined without operator attendance, once the job is set up and the “cycle start” button is pressed, the operator is free to “walk away” and do other work while the EM105H completes a block bank or main line bore unattended!

- Productivity – Up to 75% time savings over traditional machines

- Control – Touch Screen Controls located on one panel for ease of operation

- Automation – Automatically machines precise dimensions

- Flexibility – Block boring and surfacing, head surfacing, line boring and general CNC machining.

- Versatility – Change cutterheads from surfacing to boring and back in 15 seconds.

- Heavy Duty – Rottler rugged machine tool quality for accurate and long life. Heat treated mehanite cast iron castings.

- Large Diameter Spindle – All F100A machines incorporate the use of a large diameter hard chromed spindle, utilizing high precision angular contact bearings and automatic lubrication.

- Machine ways are induction hardened and coated with turcite low friction material and supplied with air pressure to reduce friction and give long service life. X-axis features Linear Roller Slideways for smooth and precise movement.

- Anti-friction Ball Screws and AC Servo motors provide precise machine positioning and rapid feed rates.

- Air power draw bar allows cutterheads to be changed in second, increasing productivity and reducing operator fatigue. The machine can be changed from boring to surfacing in less than 15 seconds.

- Automated workhead tilting system for surfacing provides “back clearance” for superior surface finish.

- Increased clearance from spindle to centerline to the machine’s column allow large castings to be set up and machined.

Rottler has combined our own in house CNC programming and machining experience with software and programming experts to develop a new conversational programming system that is easy to learn and operate. The use of Windows style icons and graphical displays makes programs easier to understand, the old fashioned abstract G&M code programming has been replaced with easy to understand conversational icons and menus.

The use of Windows information allows easy handling – everyone knows about file saving and copying to external laptops and desktop computers. Programs can be emailed worldwide via the Internet and transferred by simple USB flash memory drives.

Rottler PATH CAD/CAM (Computer Aided Design and Manufacturing) Software – While the operator is developing a program on the machine, laptop or desktop, the software is calculating things like tool paths in the background. The software is able to convert a drawing into a complex CNC program and run the machine with very little operator involvement.

- CNC (Computer Numerical Control) Machine Using Windows Operating System and Industrial PC With Intel Processor. Precision Programming and Control Thru a 19″ (483mm) Computerized Touch Screen.

- Software Options Available for Programmable & Automated Cycles Such as Boring, Surfacing, Lower Sleeve Offset Boring, Water Hole Repairs, Main & Cam Line Boring, General CNC Machine Work

- Spindle Rotation by AC Servo Motor – Infinitely Variable 0-5000RPM – 10HP (7.5kW)

- USB Flash Drive for File Transfer to and from Computer

- Machine/Computer can Operate in Either Inch or Metric System

- 3 Axis Movement by Precision Ball Screws & Ac Servo Motors – Infinitely Variable

- Horizontal Movement (X Axis) – Left and Right Direction – 132″ (3350mm)

- Horizontal Movement (Y Axis) – In and Out Direction – 16″ (406mm)

- Vertical Movement (Z Axis) – Up and Down – 29″ (736mm)

- Vertical, Horizontal and Spindle Load Monitoring for Fast Overload Shut Down

- Precision Position Display in .0001″ (.002mm) Resolution.

- Electronic Handwheel for Manual Movement – Per Click: Coarse Mode .01″ (.25mm) Medium Mode .001″ (.01mm) Fine Mode .0001″ (.002mm)

- Infinitely Variable Feedrates Adjustable by Handwheel During Automatic Cycles

- High Performance Spindle Rotation AC Brushless Servo Motor and Drive System

- Hard Chromed Precision Spindle with High Speed Angular Contact Bearings

- Fast Rapid and Jog Speeds for Reduced Cycle Time

- Automatic Workhead Tilt System for Back Clearance During Surfacing

- Air Assisted Quick Change Cutterhead Draw Bar System

- One Piece Heat Treated Mehanite Cast Iron Machine Castings

- Air Pressurized Column for Less Friction and Accurate Positioning

- Turcite Coated Slideways for Low Friction and Extended Life

- Linear Roller Slideways in the X-axis for smooth and precise movement even under heavy load.

- LED Work Light (Mounted)

- Automatic Central Lubrication System Monitored by Computer

- Chip Guard With Adjustable Pivot Arm

- Operation, Programming and Spare Parts Manual – Digital

| EM105H Machine Specifications | American | Metric |

|---|---|---|

| Control | CNC Touch Screen | |

| Touch Screen | 15″ | 381mm |

| Machine Height | 137″ | 3480mm |

| Table – Size | 33″ x 135″ | 850 x 3430mm |

| Table – T Slots | 3 | |

| Travel – Horizontal (X Axis) | 132″ | 3350mm |

| Travel – In/Out (Y Axis) | 16″ | 406mm |

| Travel – Vertical (Z Axis) | 29″ | 736mm |

| Travel – Spindle Nose to Table | 50.1″ | 1273mm |

| Travel – Spindle Center to Column | 25.5″ | 648mm |

| Spindle – Rotation Speed | 0 to 1000 RPM | |

| Spindle – Motor | 17 HP | 12.75 Kw |

| Cylinder Bore Range (with Optional Cutterheads) | .75″ – 20″ | 19 – 508mm |

| Line Bore Range (with Optional Cutterheads) | 1.9″ – 8.5″ | 48.5 – 216mm |

| Surfacing Cutterhead Diameters | 10″, 14″, 18″ & 22″ | 250, 360, 460 & 570mm |

| Dimensions – Machine | 84D x 180W x 137″ H | 2134D x 4572W x 3480mm H |

| Dimensions – Floor Space Requirements | 96D x 231W” | 2438D x 5867Wmm |

| Dimensions – Shipping | 86D x 173W x 90″ H | 2184D x 4394W x 2286mm H |

| Machine Weight | 19000 lbs | 8618 kg |

| Electrical Requirements | 208-240V, 60A, 50Hz, 60Ph | |

| Air Requirements | 1 cfm @ 90 psi | 28 l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) | |

Connecting Rod Fixture – Rottler’s patented Connecting Rod Fixtures allow large connecting rods to be surfaced and bored on the EM105H machines. The Rottler boring fixtures allow both big end and small end to be bored in one set up resulting in perfect parallelism between big end and small end. All the rods in a set can be accurately bored for equal center to center distance, a must for today’s high compression diesel engines. Special heavy duty fixtures available for boring very large, heavy connecting rods found in natural gas compressors and workboat marine engines are available.